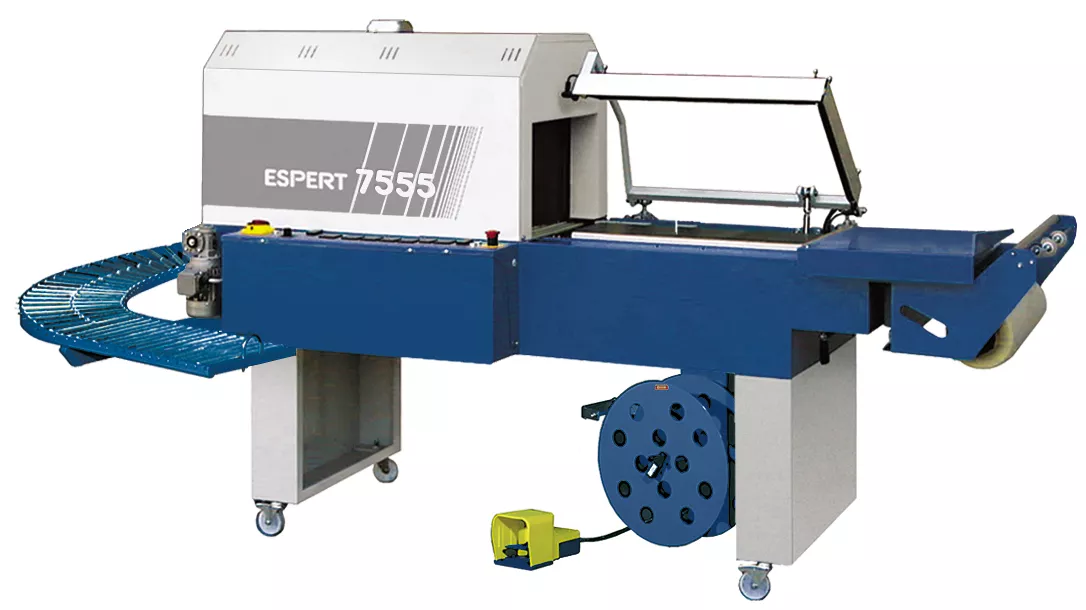

An alternative choice to “one-step®” systems in order to increase production though beeing very easy to use..

- Innovative design

- High quality standards

- High productions outputs

- Fully automatic working cycle

- Pneumatical working: a pneumatic cylinder closes the sealing-bars, this way the conveyor belt starts operating and transfers the product into the shrink tunnel for being shrinked.

- Opening and closing of the sealing-bars (with a pedal or automatically), sealing-time and conveyor belt moving time controlled by a timer

- Two independent conveyor belts in the sealing area and in the shrinking

- The height of the sealing area is adjustable according to the product size

- An efficient safety system guarantees the operator’s hands security, according to the CE regulations

- The shrink tunnel, integrated in the machine structure, is equipped with a rolling-rods conveyor belt with adjustable speed by means of a direct current variator on the control panel. The tunnel itself has shutters for air regulation in order to obtain the best shrinking even in difficult conditions.

- Available options: Boomerang roller conveyor, scrap-rewinder

- The machine works with PVC (BLUE FILM), polyolefin hot thermo-sealing and also shrinkable films (GREEN FILM –GOLDEN FILM)

Machine made according to CE rules.

SPECIFICATIONS ESPERT 7555 EV

- Power supply: 240/400 V – 3 Ph + N

- Power required: 10 KW

- Overall machine dimensions: 2730 x 950 x 1500 mm

- Working table height: 930 mm

- Tunnel entrance dimensions: 570 x 240 mm

- Tunnel lenght: 900 mm

- Weight: 340 kg

- Max sealing area: 750 x 550 mm

- Max product height: 150 mm

- Impulse sealing system: Lama superiore

- Max film width: 700 mm

- Compressed air consuption: 3 Nl/cycle

- Compressed air pressure: 6 bar

- Output: 600 – 900 pz/h

notes: Technical data subject to variations without prior notice

Output depends on the operator and the type of the package