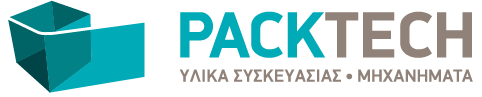

- LATERAL automatic feeding with driving system

- Pneumatic pusher for automatic feeding of multipack into the sealing area

- Sealing time electronically adjustable

- Sealing-bar with two sealing blades and one teflon-coated cutting blade controlled by electronic thermo-regulator ; pneumatic movement

- In case of any obstacle presence safety arrest of the sealing blades

- Product detected by a system of photo-eyes

- The wrapped product stays on a plate behind the sealing area till the outcoming wrapped product pushes it onto the tunnel belt conveyor that is always running

- Protections of moving parts with aluminum, polycarbonate and/or perforated sheet panels

- In-line in-feed belt conveyor running with fixed speed

- Tunnel steel zinc-coated mesh belt conveyor

- Tunnel air heating by finned resistances controlled by an electronic thermo-regulator

- Closed and forced air circulation with air flow adjustable by flaps in order to have the best shrinking

- Cooling fan at the tunnel exit included

- Internal tunnel parts made by steel zinc-coated

- External powder painting

- Double-rolls system with motorized top and bottom film-unwinding

OPTIONS:

- Customized in-feed belt conveyor

- Vertical rollers to compress the film excess at the tunnel exit

- Customized tunnel and sealing-bar height

- After-sealing-bar top-clamp to block unstable products

- Frequency AC engine controller for tunnel belt conveyor

- Inverter to adjust the control speed on the tunnel and/or sealing conveyor belt

- Discharging idle roller conveyor

- Extended tunnel carpet at the exit to allow greater cooling of the film

The machines works with single-wounded (flat) LLDPE

Machine made according to CE rules.

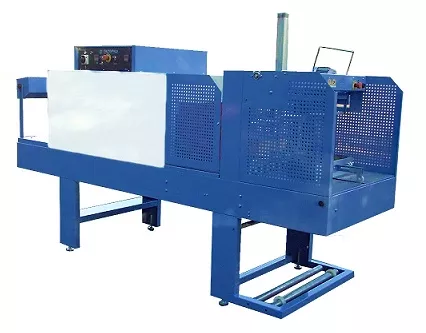

ECOFARD 500 AOL

- Sealing Bar: lenght 500 x H 240 mm pneumatically working controlled by photo-eye

- Roll sizes: 250 x 480 mm

- Max tunnel entrance: 480 X H 340 x 870 mm lenght

- Output: Up to 12 pz/min

- Power supply: 3 Ph + N + T | 220/380 V 8 KW

- Motorized film unwinder: Superior roll – Inferior roll optional

ECOFARD 700 AOL

- Sealing Bar: lenght 500 x H 380 mm pneumatically working controlled by photo-eye

- Roll sizes: 250 x 680 mm

- Max tunnel entrance: 700 X H 410 x 1300 mm lenght

- Output: Up to 12 pz/min

- Power supply: 3 Ph + N + T | 220/380 V 17 KW

- Motorized film unwinder: Superior roll – Inferior roll optional

ECOFARD 900 AOL

- Sealing Bar: lenght 900 x H 410 mm pneumatically working controlled by photo-eye

- Roll sizes: 250 x 880 mm

- Max tunnel entrance: 900 X H 500 x 1400 mm lenght

- Output: Up to 12 pz/min

- Power supply: 3 Ph + N + T | 220/380 V 24 KW

- Motorized film unwinder: Superior roll – Inferior roll